OUR CAPABILITIES

You’re looking for a manufacturing partner that not only covers all areas of manufacturing, but will deliver it to exceptional standards

ENGINEERING

SERVICES

Work with our experienced team of designers

Patriot Manufacturing has a team of highly skilled Engineers who are able to provide 3D model drawings with FEA analysis through to full fabrication drawings with Certification for our customers if needed.

3D CAD DRAWINGS

& PROGRAMMING

Patriot Manufacturing has invested in advanced 3D Modeling software such as Inventor, Autocad, Stream Bend and Boost. We can work with all types of customer model files and Autocad drawings, From STP File/ DXF files and DWG files.

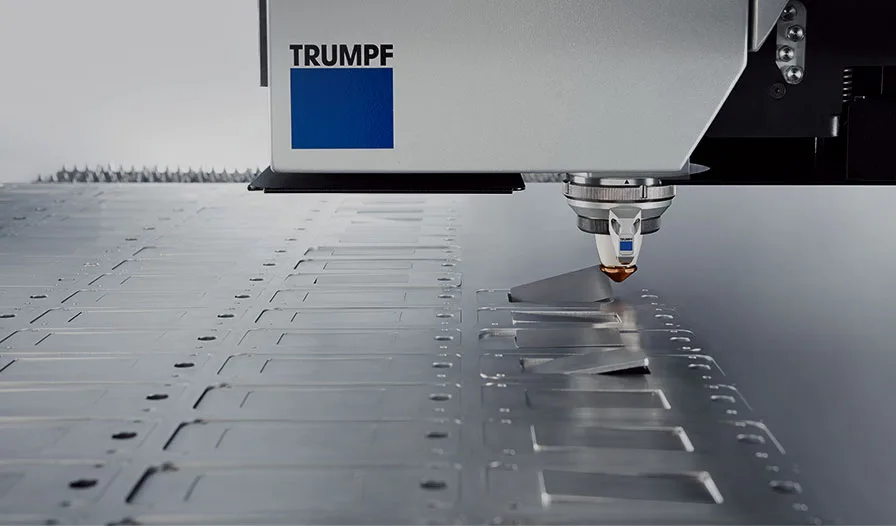

LASER

CUTTING

State of the art laser cutting equipment

Patriot Manufacturing offers precision state-of-the-art Laser Cutting used for high-quality manufacturing in sheet metal and fabrication for our clients. We are sheet metal specialists and focus on providing premium Laser Cut parts from prototypes through to high-volume production runs for all your manufacturing requirements.

TRUMPF 5030

8KW FIBRE

Cutting range 3000mm X 1500mm Sheet size capability can cut up to 25mm Thk SS/ Mild Steel and Aluminium

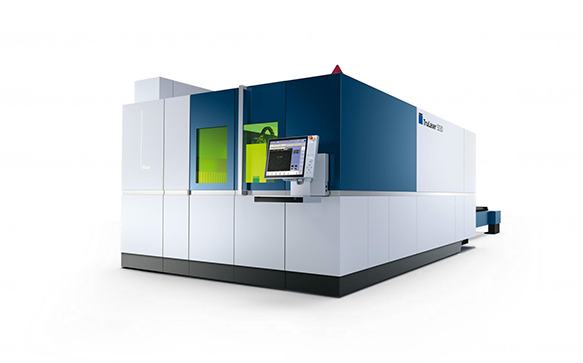

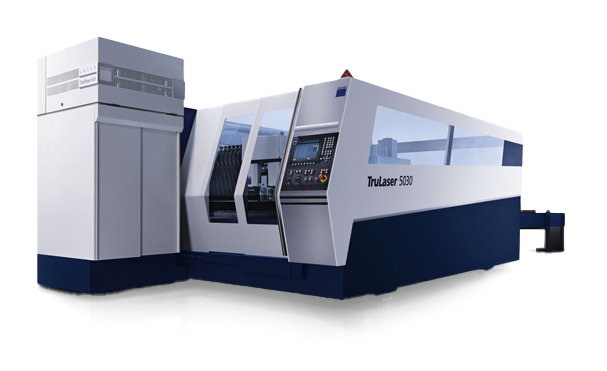

TRUMPF 5030

6KW CO2

Cutting range 3000mm X 1500mm Sheet size capability 25mm Thk SS/ Mild Steel and 15mm Thk Aluminium

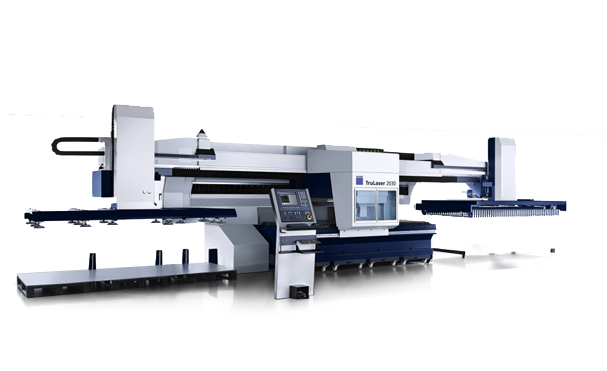

TRUMPF 2030

2KW COAX

Cutting range 3000 x 1500, material range Mild Steel 12mm, Stainless Steel 6mm and Aluminium 5mm Thk

PANEL

BENDING

Complex bending requirements

Patriot Manufacturing offers state-of-the-art bending equipment to achieve the impossible with complex bending requirements. After decades of experience forming sheet metal into amazing products our experienced design team know how to get the most out of our panel benders and can assist you with the design process to achieve your desired outcome.

CNC PANEL

BENDING

Our SALVAGNINI P2L-2225, known as the Ferrari in panel bending, is an unparalleled machine in manufacturing. The P2 integrates high productivity through automatic bending and handling cycles and remarkable flexibility via universal bending tools. With an automatic blankholder, it performs 17 bends per minute without requiring re-tooling.

Trubend 7036

36 TONNE E BRAKE

Our Trubend 7036 handles small to medium sheet metal parts (up to 1000 mm). It swiftly bends even tiny pieces, aiding efficient production of delicate parts. Its six-axes back gauge assures precise component positioning. The gauge fingers move impressively fast, covering 1500 mm/s (X axis) and 2200 mm/s (Z axis), complemented by a bending line laser for accurate part alignment.

5130 123 TONNE

HYDRAULIC BRAKE

Our TruBend 5130 is TRUMPF’s most popular press brake and delivers outstanding productivity at every stage, from programming/tool setup to bending. It features a patented ACB (automatically controlled bending) angle measuring system that guarantees bending-angle precision. You can rely on Patriot Manufacturing’s expert programmers and qualified press brake operators to get your job done right.

CNC TURRET PUNCHING

Patriot Manufacturing offers Turret Punching with a rotation of various tools offering Lovering, Forming, Bead rolling and threads. With offline tool setups and unmatched flexibility and productivity. The Our punching capabilities include a single-station punching head, as opposed to a turret punching machine, this design minimizes machine setup time so we can pass the savings on to our customers.

LINISHING & EDGE ROUNDING

Edge rounding and linishing is a process of smoothing and rounding the edges of various metals to remove any sharp or rough edges. It is a common finishing technique used in industries such as manufacturing, construction, and engineering to improve the safety and aesthetics of the finished product. Edge rounding is also very important for all parts that are powder coated it helps draw in the powder coat and stops the powder from flaking or cracking in our harsh Australian climate.

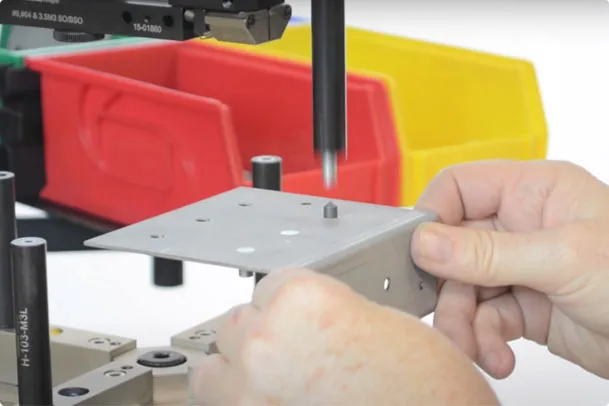

HAEGER STUD INSERTION

Our Haeger machines allow the insertion of up to four different fasteners in a single handling of a part. The technology offers the single most significant boost to hardware insertion productivity since the introduction of automatic tooling systems.

CORNER FORMING MACHINE

Our corner-forming machine makes corner welding obsolete. It offers completely new opportunities in metal sheet production of doors, panels even road signs without welding of corners or grinding them allowing a much neater finish.

CNC MILLING, DRILLING & TAPPING

Patriot Manufacturing works closely with ISO9001-certified CNC Machinist and offers the quality machining required to suit your requirements.

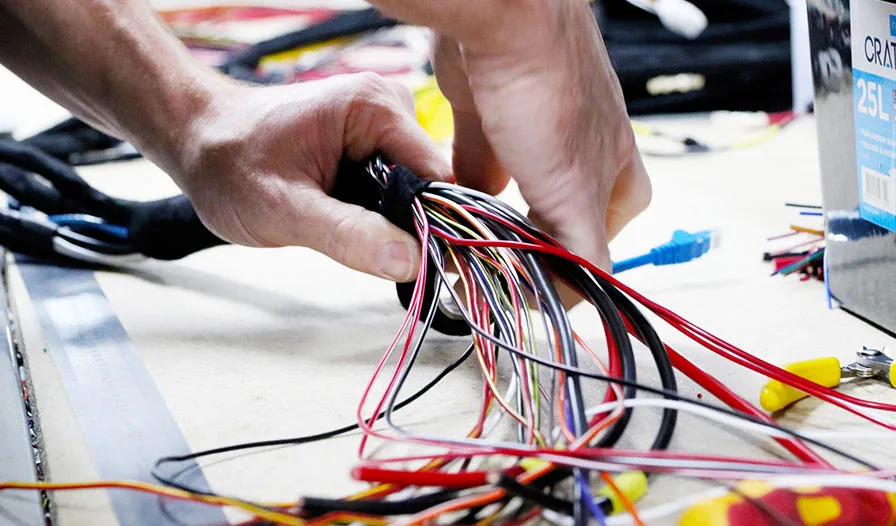

QUALIFIED ELECTRICIANS

Patriot Manufacturing has qualified in-house electricians allowing us to have the capability to wire up your electrical enclosures as required to suit various IP categories as well as Lithium ion Batteries

WELDING &

FABRICATION

At Patriot Manufacturing we specialise in precision Welding of Stainless Steel /Aluminium and Mild Steel with contaminant-free welding bays with protective screening.

FINISHING &

POWDER COATING

Patriot Manufacturing offers in-house Pre-treatment cleaning and preparation of the metal surface to ensure proper adhesion and longevity of the powder coating, basically, this means we always create a protective layer on the metal surface prior to Powder Coating for better quality and longer-lasting products. Having our state-of-the-art facility in-house we can control our quality to the highest level for your peace of mind.

FINAL ASSEMBLY

Patriot Manufacturing has full capability of assembling manufactured parts including Electrical and Mechanical fit-outs complete packaged ready for delivery.

QA &

PACKAGING

Quality assurance checking and packing are two essential processes crucial for Patriot Manufacturing ensuring product quality and safe handling and packing are completed before they are shipped to our customers. You can expect the best when dealing with Patriot Manufacturing!